- Visit our CNC Machining & Laser Cutting Website:

- T2K CNC

- +44 (0) 121 242 2000

- sales@tooling2000.co.uk

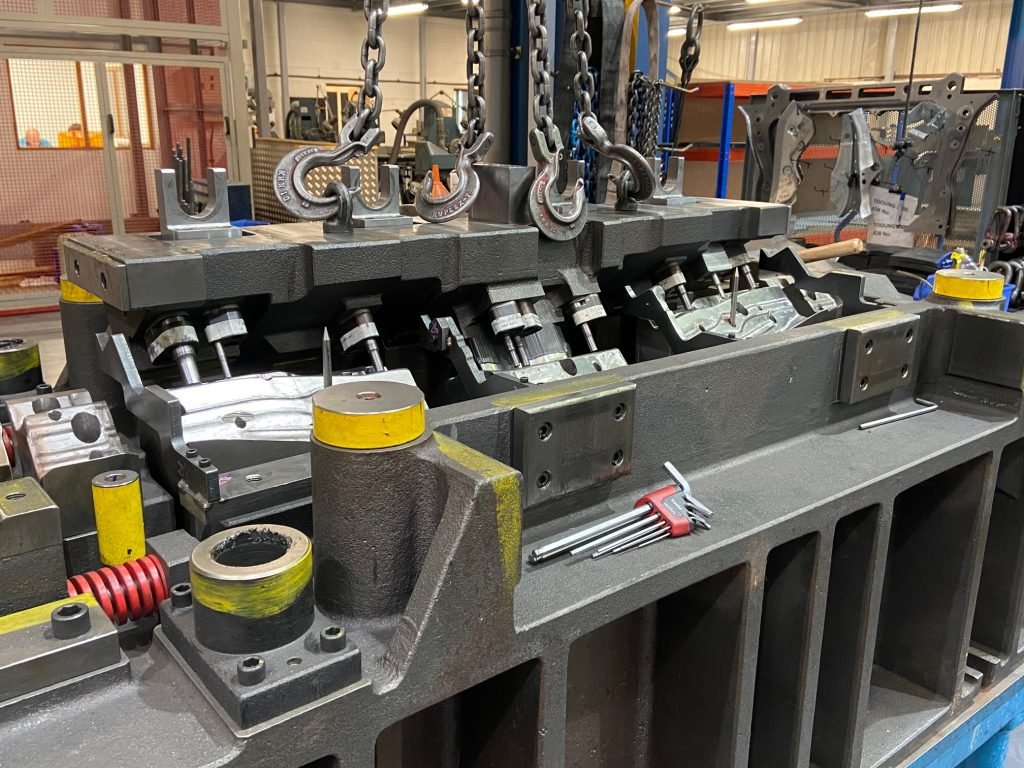

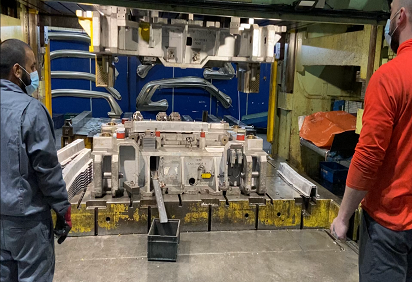

We provide specialist tooling and stamping capability for manufacturers who need consistent output and dependable delivery. Our work is built around strong toolroom expertise, supported by controlled presswork processes that help maintain accuracy over repeat production.

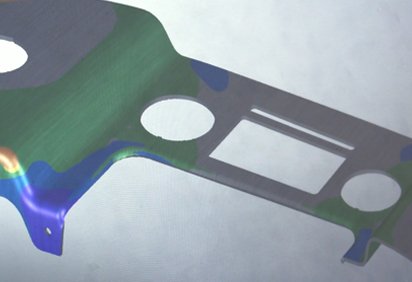

We support a wide range of requirements, from new tool builds and tool try-outs through to ongoing stamping production, tool maintenance, and modifications. Working with materials such as stainless steel, aluminium, brass, and beyond, we help customers achieve stable quality, reduce variation, and keep presswork running smoothly.

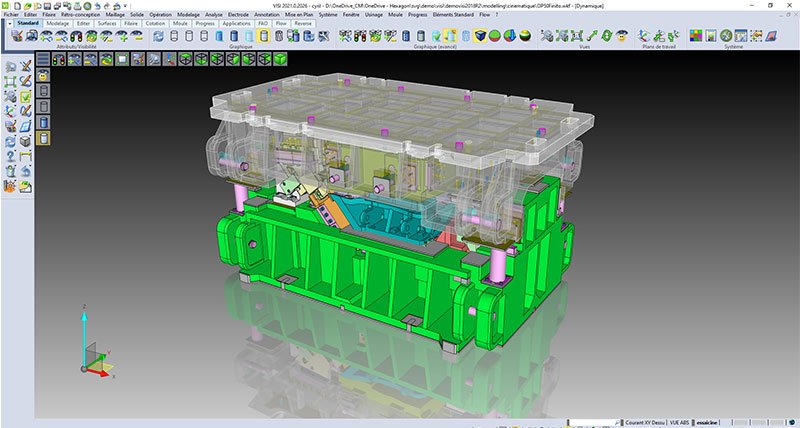

From concept to production plan, we assess risks and requirements early so you get a clear, realistic route to manufacture.

3, 4 and 5-axis CNC machining for complex geometry and tight tolerances, from one-offs through to repeat batches.

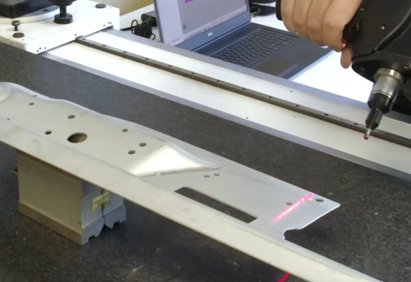

Fast turnaround prototype machining for high accuracy, flexible quantities, and full project support from brief to finished part.

Design and manufacture of tooling, jigs, and fixtures to support machining, measurement, and repeatable production.

Metal pressings and stampings delivered with process control and tooling support for consistent repeat production.

Precision laser cutting across common metals, delivered with quick turnarounds and quality-focused results.

Yes. We carry out tool maintenance, repair, refurbishment, and modifications, including updates to suit part changes or to improve repeatability and output.

We support a range of tooling approaches depending on the part and volumes, including single operation, progression, transfer, and forming and trimming tools.

Yes. We provide tool try-out and proving so performance is validated before production starts. This helps reduce risk and supports consistent, repeatable output.

We can support stamping across a wide range of sheet-metal applications. Material suitability depends on the grade, thickness, and formability, so we confirm this once we’ve reviewed your drawing and specification. We support low to high-volume production, including coil-fed work, with press capability up to a 2,500-ton mechanical press and coil handling up to 1,520 mm width and 6 mm thickness

GET IN TOUCH

We Build Capability with a passion for quality

From press tool design and precision machining to presswork, prototyping, and ongoing tool support – our capabilities are built to keep your production moving.

Get in touch today – let’s find the right route for your project.

41 Western Road Winson Green Birmingham B18 7QD

sales@tooling2000.co.uk

+44 (0) 121 242 2000

© 2025 Tooling 2000 Ltd | Registered in England No. 03273596 | VAT Reg. No. GB195384370 | Privacy Policy | Terms & Conditions