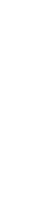

25 years of manufacturing excellence taking your ideas from feasibility through to completion all under one roof

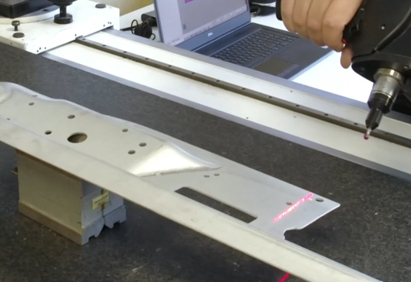

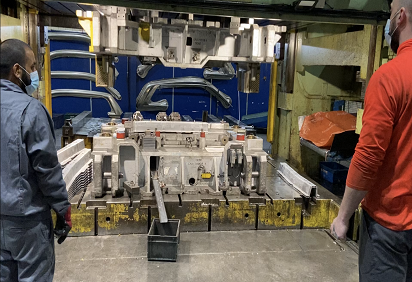

Since 1996 we have been offering tailored solutions for the metal stamping and component manufacturing industries, from initial concept and part feasibility, through to the finished component.

Working with the best

Thanks to years of experience solving tooling, presswork and sheet metal problems